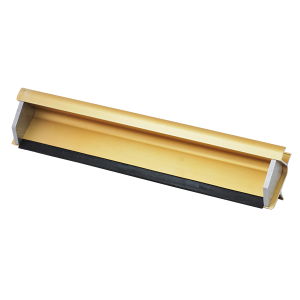

Murakami Tension Meter

Introducing the Murakami Tension Meter – Your Essential Tool for Accurate Screen Tension Measurement, Up to 60 Newtons!

Achieve precise tension control in your screen printing process with the Murakami Tension Meter. Specially engineered to measure screen tension with unmatched accuracy, this indispensable tool ensures that your prints are of the highest quality. From novice screen printers to seasoned professionals, the Murakami Tension Meter is a reliable companion that empowers you to take your craft to new heights.

$375.00

Description

Murakami Tension Meter Key Features:

- High-Resolution Tension Measurement: The Murakami Tension Meter is designed to measure screen tension with high resolution, providing you with precise readings up to 60 Newtons. With this level of accuracy, you can confidently maintain consistent tension across all your screens for flawless prints.

- User-Friendly Operation: Easy to use and understand, the Murakami Tension Meter simplifies tension measurement for every screen printer. Just place the meter on the screen mesh, apply slight pressure, and read the tension value on the clear and intuitive scale.

- Wide Range of Applications: Whether you work with fine mesh counts for intricate designs or coarse mesh counts for heavy ink deposition, the Murakami Tension Meter covers it all. It accommodates a diverse range of screen mesh types, making it suitable for various screen printing projects.

- Sturdy and Durable Build: Crafted from premium materials, this tension meter is built to withstand the demands of daily screen printing operations. Its rugged construction ensures longevity, making it a dependable tool for countless print jobs.

- Portable Design: Compact and lightweight, the Murakami Tension Meter is highly portable, allowing you to carry it effortlessly between print stations. It’s a practical solution for busy workshops, studios, and on-the-go printing events.

- Murakami Quality Assurance: Murakami is a trusted name in the screen printing industry, known for producing top-notch equipment. The Murakami Tension Meter lives up to this reputation, delivering excellence and precision you can rely on.

Why Measure Screen Tension?

Screen tension directly influences the quality and consistency of your prints. Uneven tension can lead to registration issues, poor ink transfer, and subpar results. By utilizing the Murakami Tension Meter, you can maintain optimal tension levels, ensuring that each print is vibrant, crisp, and precisely aligned.

Elevate your screen printing experience with the Murakami Tension Meter, a tool designed to bring accuracy and efficiency to your craft. From small-scale projects to large production runs, this tension meter empowers you to create professional-level prints with ease.

Discover the difference that precise tension control can make in your screen printing journey. Invest in the Murakami Tension Meter and unlock the full potential of your prints. Order yours today and take the first step towards perfection in your screen printing endeavors!

NOTE: If you are using a stretcher with an open center, it is advisable to put a net beneath in case the fabric rips.

Technical Specifications

Calibrating a Murakami Tension Meter using the glass calibration method is essential to ensure accurate tension measurements. The glass calibration method utilizes a known reference point to verify the tension meter’s accuracy. Follow these step-by-step instructions to calibrate your Murakami Tension Meter effectively:

Materials Needed:

- Murakami Tension Meter

- Glass calibration plate (or a piece of glass with a known tension value)

- Soft cloth or lint-free microfiber cloth

Calibration Steps:

- Prepare the Tension Meter: Ensure that the Murakami Tension Meter is clean and free from any debris or dust. Use a soft cloth or lint-free microfiber cloth to gently wipe the meter’s surfaces, both the contact area and the scale.

- Prepare the Glass Calibration Plate: If you have a glass calibration plate with a known tension value, make sure it is clean and free from any contaminants. If you don’t have a dedicated calibration plate, you can use a piece of glass with a known tension value. This value can be obtained from the manufacturer or a reputable calibration source.

- Place the Glass Calibration Plate: Lay the glass calibration plate on a flat, stable surface. Ensure that the glass is free from any warping or damages that could affect the calibration process.

- Zero the Tension Meter: Before proceeding with the calibration, zero the tension meter to account for any offset. To do this, gently press the tension meter onto the glass calibration plate, then set the meter’s needle to zero by adjusting the zero adjustment screw if needed.

- Apply the Calibration Force: Now, apply the calibration force to the tension meter. This force should match the known tension value of the glass calibration plate. Ensure that the tension meter’s contact area is in full contact with the glass surface.

- Read the Measurement: With the calibration force applied, read the measurement displayed on the tension meter’s scale. Compare this reading to the known tension value of the glass calibration plate.

- Adjust the Calibration (if necessary): If the tension meter’s reading matches the known tension value, then the meter is accurately calibrated. If there is a discrepancy, you may need to adjust the tension meter accordingly. Many tension meters have a calibration screw or knob that can be adjusted to match the known tension value.

- Repeat (if desired): For added accuracy, you can repeat the calibration process multiple times, taking multiple measurements and comparing them to the known tension value.

- Record and Mark: Once the calibration is successfully completed, record the calibration value for future reference. You can also mark the tension meter or its case with the calibration value to easily identify the calibrated meter.

Regular calibration is crucial to maintain the accuracy of your Murakami Tension Meter. By following these instructions and calibrating your tension meter periodically, you can ensure consistent and reliable tension measurements, leading to high-quality screen prints with optimal tension control.

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews