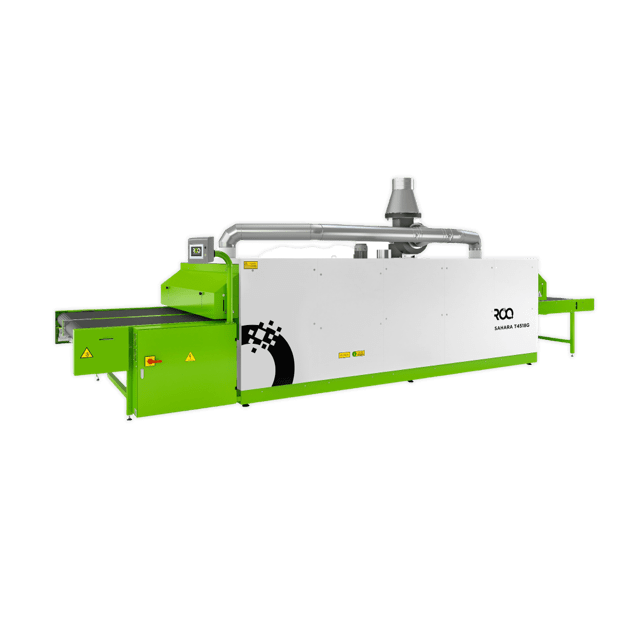

ROQ Sahara Conveyor Dryer

Introducing the ROQ Sahara Dryer – Redefining Screen Printing Drying

Step into the world of advanced screen printing drying technology with the ROQ Sahara Dryer. As a leading manufacturer of automated screen printing machines, ROQ brings innovation and efficiency to the next level with this state-of-the-art dryer.

Versatility at Its Finest: The ROQ Sahara Dryer is a true chameleon, designed to adapt seamlessly to any print shop environment. Whether you’re facing extreme weather conditions or limited power options, the Sahara Dryer can operate efficiently using gas, electricity, or a combination of both with the MIX option.

Powered by Expertise: Our partnership with INEGI, renowned for its 35 years of engineering excellence in mechanical and industrial engineering, has taken the Sahara Dryer to new heights. With a fresh perspective and meticulous research, we have refined this dryer to perfection, pinpointing weaknesses and incorporating innovative improvements.

Energy Efficiency Redefined: Embracing a greener approach, the Sahara Dryer comes with reinforced insulation and a stand-by mode, ensuring superior energy efficiency. Reduce your carbon footprint while achieving top-notch curing results.

Enhanced Performance and User Experience: We’ve raised the bar with a chamber entry height of 140 mm (5.5′), offering more flexibility for various garment types. The Sahara Dryer also boasts noise reduction technology, creating a more pleasant working environment for your team. Our updated user-friendly software includes a recipe-saving system, enabling seamless adaptation to different job-curing parameters.

Customization to Suit Your Needs: Just like its predecessor, the ROQ Sahara Dryer is fully customizable to cater to your specific requirements. With this dryer, your print shop’s curing section transforms into a small desert of productivity, achieving optimal temperatures while ensuring safety and efficiency.

Experience the Future of Drying: With the ROQ Sahara Dryer, you can take your screen printing business to new heights. Embrace cutting-edge technology, unparalleled performance, and eco-friendly solutions for your drying needs. Elevate your prints to perfection and create a thriving print shop with the ROQ Sahara Dryer. Experience the desert’s heat and efficiency in every print.

Description

Key Features of the ROQ Sahara Dryer:

- Enhanced Energy Efficiency: The ROQ Sahara Dryer is equipped with reinforced insulation, ensuring improved energy efficiency and thermal stability, resulting in cost savings and reduced environmental impact.

- Standby Mode: Take advantage of the Standby Mode during breaks or downtime to maintain the dryer’s temperature at a reduced cost, optimizing energy consumption even further.

- Increased Chamber Entry Height: Enjoy greater flexibility with an increased chamber entry height of 140 mm (5.5’), accommodating various garment types and thicknesses for seamless curing.

- Noise Reduction: The Sahara Dryer incorporates noise reduction technology, providing a quieter and more comfortable working environment for your team.

- Efficient Hot-Air Circulation: The axial flow fan ensures a constant circulation of hot air throughout the dryer, guaranteeing uniform and efficient curing of printed garments.

- Air Purification Filter: The inclusion of an air purification filter for the burner ensures clean combustion and improved air quality within the drying chamber.

- High-Performance Conveyor Belt: The antistatic and resistant mesh conveyor features a high tensile strength PTFE coated belt, enabling smooth and reliable garment transport.

- Independent Conveyor Control: Enjoy greater control over the curing process with the option of variable speed and direction for the conveyor belt, allowing for precise adjustments based on print requirements.

- Improved Maintenance: The Sahara Dryer features an improved filter access system, making maintenance tasks faster and more straightforward, ensuring consistent performance.

- User-Friendly Software: The updated software boasts a brand-new recipe saving system, empowering you to manage exposure time and overall temperature efficiently for different job requirements.

- Digital Temperature Display: Stay informed and in control with the digital temperature display, allowing you to monitor and adjust curing temperatures with ease.

- Internal Exhaustion Header System: Each module of the dryer is equipped with an internal exhaustion header system, optimizing the airflow and exhaust management for maximum efficiency.

- Contact Temperature Control: The Sahara Dryer offers precise contact temperature control, ensuring accurate curing of various ink types and ensuring the best print results.

- Temperature Range: The ROQ Sahara Dryer provides a temperature range from a minimum of 90°C to a maximum of 200°C, catering to diverse curing needs.

- Optional Dual Conveyor and Customizable Lengths: For increased productivity, the Sahara Dryer offers the option of two conveyors with independent speed and direction. Additionally, you have the flexibility to choose different lengths for entry and exit openings to match your production setup.

- Gas-Powered with Heat Exchanger: The ROQ Sahara Dryer can be powered by gas with a heat exchanger, offering reliable and efficient heating for consistent curing results.

Technical Specifications

|

ROQ SAHARA |

T3009E/G | T3011E/G | T4511E/G | T3015E/G | T4515E/G | T6015E/G | T7515E/G | T9015E/G | T3018E/G* | T4518E/G* | T6018E/G* | T7518E/G* |

T9018E/G* |

| Drying area (mm/inch) | 2700×900 / 106”x35” | 2700×1100 / 106”x35” |

4300×1100 / 169”x43” |

2700×1500 / 106”x59” | 4300×1500 / 169”x59” | 5600×1500 / 220”x59” | 7200×1500 / 283”x592 | 8800×1500 / 346”59” | 2700×1800 / 106”x71” | 4300×1800 / 169”x71” | 5600×1800 / 220”x71” | 7200×1800 / 283”x71” | 8800×1800 / 346”x71” |

| Heat power elect./gas (kW) | 22.5 / 52 | 22.5×52 | 31 / 52 | 31.5 / 70 | 36 / 70 | 63 / 140 | 68 / 140 | 72 / 140 | 36 / 70 | 36 / 70 | 72 / 140 | 72 / 140 | 72 / 140 |

| Gas LPG consumption min/max. (Nm/h | BTU) | 0.6 – 2 | 50000 – 166000 | 1.2 – 4 | 100000 – 332000 |

1.2 – 4 | 100000 – 332000 | 0.6 – 2 | 50000 – 166000 | 1.2 – 4 | 100000 – 332000 | ||||||||

| Natural gas cons. min/max. (Nm/h | BTU) | 1.5 – 4.8 | 50000 – 166000 | 3 – 9.6 | 100000 – 332000 |

3 – 9.6 | 100000 – 332000 | 1.5 – 4.8 | 50000 – 166000 |

3 – 9.6 | 100000 – 332000 |

||||||||

| Gas pressure natural gas/LPG (mbar) |

25 / 37 |

25 / 37 |

25 / 37 | 25 / 37 | 25 / 37 | 25 / 37 | 25 / 37 | 25 / 37 | 25 / 37 | 25 / 37 | 25 / 37 | 25 / 37 | 25 / 37 |

| Plant power elect./gas (kVA) | 24.5 / 2 | 24.5 / 2 | 33 / 2 | 35 / 4 | 40 / 4 | 68 / 5 | 72 / 5 | 77 / 5 | 40 / 4 | 40 / 4 | 77 / 5 | 77 / 5 | 77 / 5 |

| Module length (mm/feet) | 2900 / 9.5’ | 2900 / 9.5’ | 4500 / 14.8’ | 2900 / 9.5’ | 4500 / 14.8’ | 2900+2900 / 9.5’+9.5’ | 4500+2900 / 14.8’+9.5’ | 4500+4500 / 14.8’+14.8’ |

2900 / 9.5’ | 4500 / 14.8’ | 2900+2900 / 9.5’+9.5’ | 4500+2900 / 14.8’+9.5’ | 4500+4500 / 14.8’+14.8’ |

| Length’s entry/exit openings (mm/feet) | 1000 / 3.28’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ |

| Total height (mm/feet) | 1670 / 5.48’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ | 1726 / 5.66’ |

| Total width (mm/feet) | 1400 / 4.59’ | 1550 / 5.08’ | 1550 / 5.08’ | 2050 / 6.70’ | 2050 / 6.70’ | 2050 / 6.70’ | 2050 / 6.70’ | 2050 / 6.70’ | 2350 / 7.70’ | 2350 / 7.70’ | 2350 / 7.70’ | 2350 / 7.70’ | 2350 / 7.70’ |

| Belt’s width (mm/feet) | 900 / 2.95 | 1100 / 3.61’ | 1100 / 3.61’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1500 / 4.92’ | 1800/5.9’ – 2×850/2.78’ | 1800/5.9’ – 2×850/2.78’ | 1800/5.9’ – 2×850/2.78’ | 1800/5.9’ – 2×850/2.78’ | 1800/5.9’ – 2×850/2.78’ |

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews