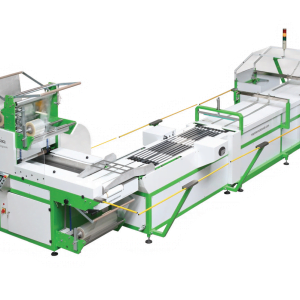

Interchange AirJet Conveyor Gas Dryer

Introducing the Interchange AirJet Gas Dryer for Screen Printing!

Experience unparalleled efficiency and cost savings with our cutting-edge Interchange AirJet. Designed with innovation in mind, this dryer boasts our patented Air Deflector recycling system, which ensures even distribution of heated air throughout the chamber. Enjoy up to 30% more efficient energy usage, translating into significant cost savings for your business.

Equipped with an exclusive Optic Sensor belt tracking system, the Interchange AirJet guarantees consistent belt performance, minimizing downtime and maximizing productivity. Say goodbye to time-consuming adjustments and hello to smooth, hassle-free operations.

$36,400.00 – $121,250.00

Description

Interchange AirJet Conveyor Gas Dryer Key Features:

- Air Deflector Re-circulating System: Revolutionary technology that evenly re-circulates heated air within the chamber, optimizing energy utilization and reducing costs.

- On-Board Diagnostic System: Advanced diagnostics for easy troubleshooting, ensuring smooth operations and minimizing downtime.

- Powerful 500,000 BTU Stainless Steel Burner: Delivering exceptional heating capacity for fast and efficient drying.

- Multiple Size Options: Available in 48”, 60”, 76”, and 86” sizes, catering to diverse production needs.

- High-Velocity Jet Nozzles: Ensuring thorough and consistent drying for impeccable results.

- Slide-Out E-Z Clean Filter: Hassle-free maintenance and cleaning to keep your dryer operating at its best.

- Graphic and Textile Models: Versatility to accommodate both graphic and textile printing applications.

- Standard 12’ Oven Section: Sufficient drying space for various screen printing projects.

- Expandable, Modular Design: Easily expand and customize your dryer setup to meet future production demands.

- ETL and CE Approved: Compliant with safety and quality standards, providing peace of mind for your operations.

Step into the future of screen printing dryers with the Interchange AirJet. Improve your productivity, achieve superior drying results, and cut down on energy expenses. Elevate your screen printing business with this game-changing dryer.

Technical Specifications

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews