Frequently Asked Questions

General

Do you offer free shipping?

We offer free shipping on supply orders of $200 or more only in the contiguous US. Some equipment we do not offer free shipping on due to the size and weight and expense of moving. However we do keep various pieces of equipment in stock and you can pick those up from our location with no shipping expense. Call or email us to see what we have in stock.

When will my online order arrive?

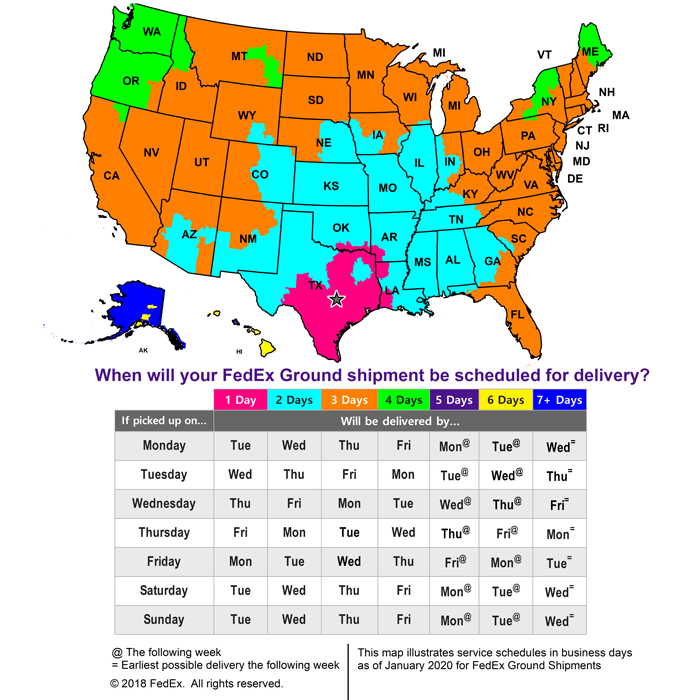

Once your online order is received and processed, you will receive an email with the tracking information. Most orders are shipped out through FedEx Ground and will arrive as soon as they can get your package to you. Keep in mind that holidays, inclement weather, and other factors beyond our control may delay your package delivery. Please use the provided tracking number to find the most up to date information on your delivery. Below is a map showing the estimated delivery time for a FedEx ground package once it leaves our facility.

Keep in mind these are estimated delivery times, not guaranteed. River City Supply is not responsible for delays in shipping that are out of our control.

Does “Same-day shipping” mean I will get my order today?

“Same-Day Shipping” means that we will process, fulfill, box, and ship your order today. Provided that the order was completed and received before the Same-Day Shipping cutoff of 3:30pm CST. Please refer to the map under “When will my online order arrive?” for an estimated shipping time frame. If your order is needed today, select either “In-Store Pickup” or “Courier” in the shipping options (Courier is only available for customers in certain zip codes in the Austin area and has a 1:00pm CST cutoff time).

How do I select “Curbside” for my online order?

During your checkout process, click on the red “Shipping Options” button. Then click on the drop down menu and select “Curbside” from the list and click on “Continue”. Complete your payment information and submit your order. You will receive an email notification once we have your order ready for pick up.

Do you price match on screen printing products?

We will do our best to match competitor pricing, however we do not guarantee it.

Do you carry eco-friendly products?

Yes, please see our Industry Trends Page to learn more about our environmentally safe products.

Can I come to your location to pick up my order?

Yes, We are doing curbside pick ups. Simply place your order online and select curbside as the delivery we will get everything ready. Once you receive your completed email simply park in one of our numbered spots and give us a call and we will bring your order to you.

Why am I being charged sales tax?

- We must have your Texas Sales and Use form on file for your orders to be sales tax exempt. Your Federal EIN number is not your Texas Sales and Use number, sales tax is collected by the state not the federal government.

- You will need to add your Texas Sales and Use number to your online profile if you are ordering through the website. Maintaining and managing your sales tax ID is your responsibility. Once you have created an online profile you will need to click on your user name and go into the tax section and simply add the number. When checking out on the very last screen you will find a button that says “Make my order tax exempt”, that you will need to click to remove the sales tax.

- If you are outside of the State of Texas we currently do not need to collect sales tax, but the laws are changing on this and we may need to start in the future.

Film Positive Questions

What are the benefits of a waterproof film?

Waterproof films offer a number of advantages. They dry faster after printing. AccuArt3 and AccuBlack have a special coating that helps to receive the dye-based ink and help it to dry instantaneously. This means there is little to no waiting for positives to dry, and no fear of smearing or marring the image during handling. The waterproof nature is also a benefit in the screen room. If the positive gets wet, the image will not be ruined. Simply allow the positive to dry and re-use.

What side of the film do I print on?

With all AccuArt products, you need to print on the coated side of the film. With AccuMark, it’s easy to determine the proper side. With AccuArt3 and AccuMark, the coated side has a very matte, slightly frosty appearance. The opposite side is very shiny. With AccuBlack, the differences are more subtle. The coated side has a duller, more matte appearance. To the touch, it appears to have a bit more tack versus the smooth and shiny opposite side. Be sure to load the film appropriately into your printer. For front tray-feed printers, load the film coated side down. For back-feed printers or if you’re using rolls, feed with the coated side facing up.

Do I need any special software to use these films?

For the most part, no. AccuArt inkjet films are designed to integrate into your graphics work flow. The only software you may need to buy is a RIP (raster image processor), if you’re not already using one. The RIP is helpful in creating color separations and also helps to improve print quality. We recommend the AccuRIP Black Pearl.

Why do I have to use dye-based inks with these films?

Dye-based inks are recommended because they actually penetrate into our special coating on the film. This aids in improving density, speeding up dry times and is integral in the waterproof nature and permanence of AccuArt and AccuBlack. Pigment based inks do not commonly work as well because they tend to remain on the film’s surface. This usually will result in longer drying times, a lack of density and lesser durability (ink is more likely to scratch off or run in wet/humid conditions).

I tried printing out a positive and the image quality is not good. What am I doing wrong?

This could be caused by a number of factors: 1. Check to see that digital artwork is of adequate resolution. Line art should be at a resolution of 1200 dpi. Color or grayscale art should be at a minimum of 300 dpi. 2. Check to see that you are printing at a proper resolution. Positives should be printed at a minimum of 720 dpi. 1440 dpi is recommended. 3. Be sure to choose a film media from your printer properties menu. This tells the printer what type of media is going through the printer. 4. Are you using a RIP? The RIP typically will improve print quality, resulting in smoother line edges and clean halftone dots if you’re doing separations. The AccuArt films can handle halftones up to 65 lpi.

What are the advantages of positives created by inkjet printers?

Inkjet positives offer a number of advantages. 1. Equipment cost is a lot lower. Inkjet printers are relatively inexpensive, and typically cost a fraction of what laser printers and imagesetters cost. 2. Accu Products are clear films with excellent density, which means that they will properly expose your screen. Vellums and some other media, are more opaque in nature, which means the light will not transfer as easy during exposure. This will sometimes result in underexposure. Another concern is often the toner (black) areas of the positive are not opaque enough to block out light. This may cause light to transfer through these areas, leading to improper exposure which may yield imaging and washout problems. 3. Inkjet printing is a cold process. With laser and thermal printers, heat is involved in the process which can cause image distortion and shrinkage of the media. Yellowing is particularly evident with thermal printing.

Are my inkjet positives reusable? How do I store inkjet positives?

Positives made with AccuArt inkjet films can easily be archived for later use. For best results, store the positives in a cool, dry area and interleaf with clean newsprint.

Why is my inkjet film positive not printing dark enough?

This could be caused by a number of things: 1. Make sure that you printed on the coated side of the film. 2. Did you use the proper print settings? For best results, print at a resolution of 1440 dpi and use a print setting for film media. You may need to experiment to find the best media setting for your printer. 3. If you’re doing positives/negatives, print with black ink only versus color. If you’re in color mode, sometimes the printer will mix the colors to make black opposed to getting a pure black ink print. 4. Make sure that you’re using dye-based inks. The dye-based inks penetrate into the film, yielding better density. Pigment based inks will remain on the surface which will typically yield less density.

How do I read Chromaline film lot numbers?

Example Lot # U25401

U – Year the product was produced: A = 2007, Z = 2006, Y = 2005, X= 2004, W= 2003, U= 2002, etc.

254 – Julian Date (day of the year) that the product was produced (254 represents September 10th)

01 – Internal Code

Please note that in addition to the lot number, diazo bottles also show an expiration date. (“Use by…”)

Film Positive Questions

What are the benefits of a waterproof film?

Waterproof films offer a number of advantages. They dry faster after printing. AccuArt3 and AccuBlack have a special coating that helps to receive the dye-based ink and help it to dry instantaneously. This means there is little to no waiting for positives to dry, and no fear of smearing or marring the image during handling. The waterproof nature is also a benefit in the screen room. If the positive gets wet, the image will not be ruined. Simply allow the positive to dry and re-use.

What side of the film do I print on?

With all AccuArt products, you need to print on the coated side of the film. With AccuMark, it’s easy to determine the proper side. With AccuArt3 and AccuMark, the coated side has a very matte, slightly frosty appearance. The opposite side is very shiny. With AccuBlack, the differences are more subtle. The coated side has a duller, more matte appearance. To the touch, it appears to have a bit more tack versus the smooth and shiny opposite side. Be sure to load the film appropriately into your printer. For front tray-feed printers, load the film coated side down. For back-feed printers or if you’re using rolls, feed with the coated side facing up.

Do I need any special software to use these films?

For the most part, no. AccuArt inkjet films are designed to integrate into your graphics work flow. The only software you may need to buy is a RIP (raster image processor), if you’re not already using one. The RIP is helpful in creating color separations and also helps to improve print quality. We recommend the AccuRIP Black Pearl.

Why do I have to use dye-based inks with these films?

Dye-based inks are recommended because they actually penetrate into our special coating on the film. This aids in improving density, speeding up dry times and is integral in the waterproof nature and permanence of AccuArt and AccuBlack. Pigment based inks do not commonly work as well because they tend to remain on the film’s surface. This usually will result in longer drying times, a lack of density and lesser durability (ink is more likely to scratch off or run in wet/humid conditions).

I tried printing out a positive and the image quality is not good. What am I doing wrong?

This could be caused by a number of factors: 1. Check to see that digital artwork is of adequate resolution. Line art should be at a resolution of 1200 dpi. Color or grayscale art should be at a minimum of 300 dpi. 2. Check to see that you are printing at a proper resolution. Positives should be printed at a minimum of 720 dpi. 1440 dpi is recommended. 3. Be sure to choose a film media from your printer properties menu. This tells the printer what type of media is going through the printer. 4. Are you using a RIP? The RIP typically will improve print quality, resulting in smoother line edges and clean halftone dots if you’re doing separations. The AccuArt films can handle halftones up to 65 lpi.

What are the advantages of positives created by inkjet printers?

Inkjet positives offer a number of advantages. 1. Equipment cost is a lot lower. Inkjet printers are relatively inexpensive, and typically cost a fraction of what laser printers and imagesetters cost. 2. Accu Products are clear films with excellent density, which means that they will properly expose your screen. Vellums and some other media, are more opaque in nature, which means the light will not transfer as easy during exposure. This will sometimes result in underexposure. Another concern is often the toner (black) areas of the positive are not opaque enough to block out light. This may cause light to transfer through these areas, leading to improper exposure which may yield imaging and washout problems. 3. Inkjet printing is a cold process. With laser and thermal printers, heat is involved in the process which can cause image distortion and shrinkage of the media. Yellowing is particularly evident with thermal printing.

Are my inkjet positives reusable? How do I store inkjet positives?

Positives made with AccuArt inkjet films can easily be archived for later use. For best results, store the positives in a cool, dry area and interleaf with clean newsprint.

Why is my inkjet film positive not printing dark enough?

This could be caused by a number of things: 1. Make sure that you printed on the coated side of the film. 2. Did you use the proper print settings? For best results, print at a resolution of 1440 dpi and use a print setting for film media. You may need to experiment to find the best media setting for your printer. 3. If you’re doing positives/negatives, print with black ink only versus color. If you’re in color mode, sometimes the printer will mix the colors to make black opposed to getting a pure black ink print. 4. Make sure that you’re using dye-based inks. The dye-based inks penetrate into the film, yielding better density. Pigment based inks will remain on the surface which will typically yield less density.

How do I read Chromaline film lot numbers?

Example Lot # U25401

U – Year the product was produced: A = 2007, Z = 2006, Y = 2005, X= 2004, W= 2003, U= 2002, etc.

254 – Julian Date (day of the year) that the product was produced (254 represents September 10th)

01 – Internal Code

Please note that in addition to the lot number, diazo bottles also show an expiration date. (“Use by…”)

Emulsion Questions

Which Emulsion is best?

We get asked this all the time and there is no way to answer without the follow up question; “what inks are you printing with? how much detail is in your designs?”

Our most popular emulsions are Chromaline Chromablue and Murakami HV and Murakami HVP. All three of these emulsions are pure photopolymers, with fast burn times, hold up great to plastisol inks, and reclaim easily if exposed properly. While photopolymers are excellent for fast exposure times and printing plastisol; they do not pick up as much detail as some of the dual cure emulsions out there. Dual cure emulsions have a diazo added to them, and by their nature expose much slower than a photopolyer. While dual cure emulsions expose much slower; they are more durable, pick up more detail, and have a wider range for over and under exposing times.

If you are printing with water based inks you have several options: Chromaline CP-Tex (our most popular), Murakami HV & Murakami HVP, Murakami SP-1400, and Murakami Photocure Pro. While all these emulsions are made to hold up to water based inks, for long runs emulsions can require the help of an emulsion hardener. Murakami MS Harder, and the more permanent Murakami Hardner A&B.

How long should I expose my screens?

No one can tell you your exposure time and be 100% correct. Every light source is different, bulbs vary, distance from the bulbs, coating techniques and thicknesses. The only way to get your emulsion dialed in on your light table is guessing and wasting time and emulsion; or just get an exposure calculator. This tool allows you to over expose one screen and it will tell you your correct exposure time.

How can I tell if my screen is underexposed?

Touch the inside of the screen during washout. If the stencil is slimy or you get color on your finger, it is a sure bet that it is underexposed. Use an exposure calculator to determine your proper exposure calculator.

Why does my dual cure emulsion break down with water-based ink?

Many people in our industry believe the “dual” in dual cure means that this emulsion is resistant to both solvent and water-based inks. Although many dual cure emulsions are resistant to both inks, this statement is not correct. The “dual” in dual cure means that the emulsion uses two sensitizers. One is already in the emulsion before mixing, and the other is usually a Diazo that is added to the emulsion by the user. For example our UDC-HV dual cure emulsion is not recommended for water-based inks, but our UDC-2 and UDC-ACE are recommended for both water and solvent-based inks.

Which stencil system is better, capillary film or direct emulsion?

They both work very well. What’s important is what will work best for your application. Direct emulsions are generally more resistant to rough treatment due to abrasion and solvent resistance. Films will usually yield sharper line edge definition.

How do I read Chromaline lot numbers?

Example Lot # U25401

U – Year the product was produced: A = 2007, Z = 2006, Y = 2005, X= 2004, W= 2003, U= 2002, etc.

254 – Julian Date (day of the year) that the product was produced (254 represents September 10th)

01 – Internal Code

Please note that in addition to the lot number, diazo bottles also show an expiration date. (“Use by…”)

Plastisol Ink Questions

How do I print on polyester shirts without getting dye migration?

“Dye Migration” occurs when garment dyes migrate up into the ink film, changing the colors of the printed inks. You may have seen red 50/50 t-shirts printed with white ink. That printed white ink may have turned a pinkish color over time due to “dye migration”.

- To prevent dye migration use a low bleed series plastisol ink; these inks have dye blockers in them to make it difficult for the dyes in the shirt to penetrate through the ink.

- There are also some low cure inks that do not require as much heat to cure the ink which helps tremendously; because heating the dyes in the shirt is what makes the dye migration start. Excalibur’s 1550 Series is a great option for a low cure ink.

- Use a low mesh screen to lay down a thick layer of ink; we recommend an 86 mesh screen.

- When coating your screens with emulsion do multiple passes with the rounded side of your scoop coater. You want to make a tall ink deposit; so with every pass you are laying down a good amount of ink. Depending on which emulsion you are using the recommended number of layers can vary.

- Use a high solid content emulsion. By using a thicker emulsion you can achieve a taller ink deposit. A good emulsion for this is Murakami HS High Density Emulsion.

- Print an underbase and or do a print flash print to get multiple layers of ink.

- Do not over cure the inks! Heat is what causes this so you only want to run your dryer the require temperature to set the ink and then get it out of the conveyor.

- Always test a shirt before proceeding with a long run; dye migration can take hours and in some cases days to show up.

What causes plastisol ink to build up?

There are a few causes of ink build up on the under side of screens; type of inks being used, mesh tension, thickness of mesh thread, emulsion over mesh (EOM). First check to make sure the plastisol ink series you are using is made for wet on wet printing (WOW). Next check your screens and make sure they are tensioned to the mesh specifications. Low tension will cause build up; and increasing squeegee pressure is what most printers do to compensate for the poor print; however too much pressure amplifys build up in WOW printing. Thread thickness plays a key role in WOW printing; you want to use the finest mesh available with a good open area (if properly tensioned) you should be able to back off your squeegee pressure and just let the inks fall through the mesh without jamming the mesh into the shirt. Emulsion coating plays a role as well; make sure you have a good coat of emulsion on your screens; depending on the thickness of the thread in your mesh you may need to do multiple coats of emulsion on the print and squeegee side of the screen.

The simple easy fix is adding process clear to your inks to lower your inks viscosity and remove some of the tackiness; or spray Sprayway 945 Silicone Spray on the underside of the screens.

How can I tell if plastisol ink is fully cured?

The definitive test to determine if plastisol inks are cured is a wash test, which is washing the garment in hot water with a strong detergent. Generally it will take from 5-10 washings to fully test the cure, but if the ink is seriously under cured, the print will show deterioration after only 1-3 washings. There are two other tests commonly used to check ink cure. The most popular test is to stretch the print about 2/3 of the total stretch of the T-shirt. If the print cracks badly and does not retract when the fabric is released, the ink is probably under-cured. The stretch test does not always work on thick deposits of ink, such as with on athletic jerseys, where the top layer of ink may stretch but the ink deep down in the fabric may be under-cured.

Another test for curing can be done by placing a few drops of ethyl acetate onto the back of the ink on the inside of the garment. This spot of ink is then placed onto an area of unprinted garment and burnished or held tightly together for two minutes. If there is a transfer of ink to the unprinted area, the ink is not fully cured and the garment should be run through the dryer again. Like the stretch test, this test is not always accurate. Ethyl acetate is a fairly hazardous chemical.

If the ink is under cured, you can run it through the dryer again and complete the cure.

Where should I store my plastisol inks?

Store in closed containers at 65 to 95 degrees F.(18 to 32 C.). Prolonged exposure to temperatures above 95º F (32º C) can cause the ink to start to gel while it’s still in the container. Keep out of direct sun light.

How can I increase the opacity of my plastisol inks?

Add 0.5 to 1.0 % M00010 Thickener #3 to increase the viscosity of the ink. The ink will set higher on the garment surface and give more opacity. Thickener #3 must be thoroughly mixed into the plastisol ink.

What do I need to screen print on Nylon?

To print on nylon and lycra fabrics you need to add a catalyst to your existing plastisol inks. The Excalibur X150 Nylon Bonding Agent works as a bonding agent to adhere the ink to the fabric. This product is mixed in a ratio of 15% catalyst to 85% plastisol ink.

How do I screen print Puff Ink?

- Use Printers Choice Puff Additive(25% – 40% by weight).

- Use coarse-mesh fabric (38-86) for high puff and finer meshes (110 -125) for lower and detail puff.

- Use a “thick” stencil/ emulsion screen. Murakami HS Photopolymer Emulsion

- “Stack” the print (print – flash-print) for extra high effect.

- Print an under base so the puff has a base plate to push upward instead of down into the fabric.

- Do not cure too hot or too long, as puff can collapse under too much heat.

- When printing large solids, use half-tone dots/mezzotints to avoid “puckering.”

- Always print puff as the last color.

How much squeegee pressure should I use?

The less pressure is better! Only use what you actually need. Too much pressure can cause ink build-up, dot gain/ smearing, excessive penetration (less opacity), reduced ink mileage. You can achieve less pressure by keeping your screens tension level high, using a thinner mesh with a more open area like the Murakami S-mesh, thinning your inks down with curable reducer or process clear.

How do I print on Spandex or stretchy materials?

Spandex and other stretchy materials can be printed on with your traditional plastisol inks, but you need to add stretch additive to the ink, stretch additive gives the ink more elasticity and the ability to flex with the garment.

Why are my inks cracking or washing out when the garments are laundered?

Under cured! Plastisols must hit 325 Degrees for a minute to a minute and half. In some cases it may be one color washes out and the other color stays in on the shirt just fine. This can happen for a number of reasons:

- Some inks are thicker or thinner than the others; the thicker the ink is the longer it requires for a full cure. (White inks, and metallic inks are usually thicker and the first to wash out if it is under cured.)

- Lower mesh on the color that washed out causing the ink deposit to be thicker; and the heat not fully curing all the way through to the bottom of the image.

- Over loaded ink with an additive; always check how much of any additive you can add to any ink before mixing.

- Multi layers of inks; when multiple colors are printed over one another the heat takes longer to penetrate all the way through to the bottom ink color.

Screen & Mesh Questions

What mesh screen should I use?

Screen Printing Equipment Questions

What is the current lead time on Vastex Equipment

Note: This equipment will drop-ship from the manufacturer, and your order will ship complete as one shipment. Below are the current lead times.

Water Based Ink Questions

Which Matsui Inks are High Solid Acrylic?

Matsui makes many of their water base products that are high solid acrylic inks also known as HSA Inks. High solid acrylic inks are developed to be used to get better coverage on polyester and difficult blends. All of these inks can be used in conjunction with the Matsui Neo Pigments for colors.

Matsui HSA Inks:

- Stretch Clear

- Matsui Stretch Mat

- Matsui Stretch White

- Acrylicon Clear

- Acrylicon White

- Kombat White

How do I keep water based inks from drying in my screen?

Keeping water based ink wet in the screen can be a challenge, especially in warmer climates, and warmer times of the year. There are some tricks you can use to help assist you in printing water based inks on press.

- Mix your inks well in the container prior to loading ink in the screen.

- Keep your screens flooded! When you are registering or need to stop during a print run, make sure to keep your screens flooded.

- Use additives such as Matsui Retarder or Matsui Quick Additive to the inks which are made to help slow drying of the inks.

- When possible place your flashes away from the screens with ink, especially the white ink. If your press is big enough it is a good idea to leave cool down stations after the the final flash. Different from plastisol you are using your flash more to keep your pallets about 140 degrees, and the warm pallets actually flash the ink rather than using the flash to cure the ink. If your pallets start getting too hot you will start getting screens closing in and building up.

- Maintain a steady supply of fresh ink to the screens. Fresh ink goes a long way to help rehydrate the inks. It is a better idea to have a less amount of ink in the screen and add it more frequently, than just load your screen with too much ink only to have it pushed to the side of the squeegees.

- Have a spray bottle of water near by to mist the inks to help rehydrate the inks if they start to look less fluid.

- Make sure there are no fans or vents blowing on the screens on press.

- If your shop has bay doors make sure to keep them closed on a windy day.

What is the difference between the Matsui Infinity and Alpha series of ink systems?

The Matsui Infinity Ink System is a color mixing system in which all the colors in the system are ready for use or can be mixed into each other to make other colors. The best feature of this system is you can follow the formulas in your Pantone color guide book without needing to use software, making it the quickest and most economical way to make custom colors. The Infinity system is excellent for 100% cotton, blends, and Polyester (with Under Base Blocker).

The Matsui Alpha Ink System is a color mixing system in which all the colors in the system are ready for use or can be mixed into each other to make other colors. The best feature of this system is you can follow the formulas in your Pantone color guide book without needing to use software, making it the quickest and most economical way to make custom colors. In addition, this system can be used for both Discharge Printing & Regular Printing. Add 5% discharge agent by weight to activate ink in order to discharge compatible fabrics. Be sure to only mix what you plan to use, and test before production.