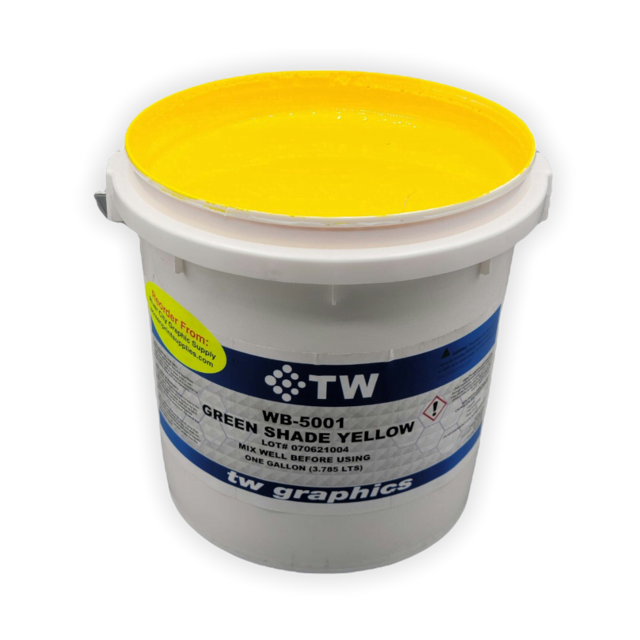

TW 5001 Gloss Green Shade Yellow Water Based Poster Ink – Perfect for Flat Stock

Elevate your poster printing game with TW Graphics® 5000 Gloss Water-Based Inks. Unleash a new realm of vibrant and captivating colors that breathe life into your poster designs. These inks are meticulously crafted to ensure impeccable adhesion, durability, and a stunning gloss finish that sets your posters apart. Experience the perfect fusion of innovation and artistry as you create posters that leave a lasting impression.

TW 5000 Gloss Water-Based Inks are not limited to posters alone. With their versatile formulation, they’re the ideal choice for crafting a diverse range of visual wonders. From fine art serigraphs and nameplates to skateboards, posters, aircraft interiors, and point of purchase displays, these inks open doors to boundless creative possibilities. Redefine your printing experience and transform ordinary posters into extraordinary works of art.

Pantone: Yellow C, PMS#102C (Gloss Finish)

$79.99 – $184.18

Description

The 5000 Gloss Ink Series has been specifically formulated to adhere to a wide range of substrates offering rich, gloss colors. End uses include fine art serigraphs, nameplates, skate boards, posters, aircraft interiors, and point of purchase displays.

TW 5000 Gloss Key Features:

- An Extensive Adhesion Range: Immerse yourself in creative freedom as our ink adheres flawlessly to an astonishing array of substrates. From Treated Coroplast™ to Polycarbonate, Tyvek® to Pressure Sensitive Vinyl, your designs will find a perfect canvas, ensuring your artwork speaks volumes.

- Brilliant Colors, Gloss Finish: Witness your designs come alive with a brilliant burst of colors that captivate the eye. Our ink provides a captivating gloss finish that adds a touch of sophistication to your prints, making every creation a masterpiece.

- Effortless Clean-Up: Experience hassle-free printing sessions with easy clean-up. Our ink’s water-based formula ensures that cleanup is a breeze, allowing you to focus more on your creative process and less on maintenance.

- Long-Lasting Brilliance: Preserve your artistry for years to come with up to 5 years of light-fastness*, ensuring that your prints retain their vibrancy and allure even when exposed to the elements.

- Automotive Grade Pigments: Elevate your prints to the level of automotive excellence with pigments that meet the demanding standards of the automotive industry. Your prints will radiate with the same quality and durability found in top-tier vehicles.

Substrate Application:

- Treated Coroplast™ / Fluted Polyolefin**: Turn ordinary surfaces into vibrant canvases with our ink’s impeccable adhesion to treated Coroplast™ and fluted polyolefin materials.

- Pressure Sensitive Vinyl: Bring your designs to life on pressure-sensitive vinyl, creating captivating visuals that adhere flawlessly to various surfaces.

- Treated Polyethylene: Imprint your creativity on treated polyethylene surfaces, ensuring your prints are as enduring as they are enchanting.

- Polystyrene (Styrene): Elevate your prints on polystyrene substrates, adding a layer of sophistication to your artwork.

- Treated Polyester (Substrate not Fabric): Make a lasting impression on treated polyester, creating prints that command attention and admiration.

- Polycarbonate: Embrace the durability of polycarbonate as your canvas, resulting in prints that withstand the test of time.

- Coated Wood: Infuse your designs onto coated wood, transforming it into an artistic masterpiece.

- Card Stock: Turn card stock into an avenue for creativity, giving your prints a touch of elegance and charm.

- Tyvek®: Experience the exceptional adhesion of our ink on Tyvek®, ensuring your designs captivate and endure.

- Tedlar®: Elevate your prints on Tedlar®, creating visuals that reflect your unique style and innovation.

- PVC: Imprint your creativity on PVC, producing prints that are as dynamic as they are durable.

- ABS: Transform ABS into an artistic canvas, bringing your imagination to life with exceptional precision.

Empower your prints with the TW Graphics® 5000 Multi-Purpose Water-Based Series – Gloss: Where Creativity Knows No Boundaries.

Technical Specifications

TW Stock Colors and Corresponding Pantones:

When mixing Pantone colors using your Pantone guide, the corresponding colors below serve as your reference for stock colors. Utilize the following formula directly from the Pantone book, combining these colors to achieve a result that closely matches your desired Pantone shade.

| TW PART# | TW DESCRIPTION | PANTONE |

| WB 5001 | GLOSS GREEN SHADE YELLOW | PMS# 102C / PANTONE YELLOW C |

| WB 5002 | GLOSS RED SHADE YELLOW | PMS# 2010C |

| WB 5003 | GLOSS YELLOW SHADE RED | PANTONE ORANGE 021C |

| WB 5004 | GLOSS BLUE SHADE RED | PMS# 7620C |

| WB 5005 | GLOSS MAGENTA | PMS# 864C |

| WB 5006 | GLOSS MAROON | PMS# 216C |

| WB 5007 | GLOSS VIOLET | PANTONE VIOLET C |

| WB 5008 | GLOSS RED SHADE BLUE | PMS# 2747 C |

| WB 5009 | GLOSS GREEN SHADE BLUE | PMS# 2175 C |

| WB 5010 | GLOSS BLUE SHADE GREEN | PMS# 3285 C |

| WB 5011 | GLOSS YELLOW SHADE GREEN | PMS# 340 C |

| WB 5012 | GLOSS GREEN SHADE YELLOW | PANTONE YELLOW C |

| WB 5013 | GLOSS MEDIUM YELLOW | PMS# 116 C |

| WB 5014 | GLOSS FIRE RED | PMS# 2347 C |

| WB 5015 | GLOSS RUBINE RED | PMS# 675 C |

| WB 5016 | GLOSS WARM RED | PMS# 1788 C |

| WB 5017 | GLOSS EMERALD GREEN | PMS# 2245 C |

| WB 5018 | GLOSS PROCESS BLUE | PMS# 2173 C |

| WB 5019 | GLOSS REFLEX BLUE | PMS# 293 C |

| WB 5020 | GLOSS ULTRA BLUE | PMS# 662 C |

| WB 5056 | GLOSS M&M PURPLE | PMS# 2395 C / PMS# 240 C |

| WB 5060 | GLOSS IRON OXIDE YELLOW | PMS# 154 C |

| WB 5061 | GLOSS BURNT SIENNA | PMS# 7583 C |

| WB 5062 | GLOSS IRON OXIDE BROWN | PMS# 7596 C |

| WB 5063 | GLOSS RAW UMBER | PMS# 7575 C |

| WB 5067 | GLOSS ULTRAMARINE BLUE | PMS# 2386 C |

Technical Specifications: TW Graphics® 5000 Series Water-Based Poster Ink:

The TW Graphics® 5000 Series Water-Based Poster Ink is a versatile and flexible one-component ink system, meticulously engineered to deliver exceptional performance across an expansive range of applications. Proudly crafted in the United States and celebrated throughout North and South America, this ink series amalgamates innovation and functionality, reshaping the landscape of printing standards.

Key Features:

- Adhesion: Boasting an exceptional adhesion profile, this ink adheres seamlessly to an eclectic array of substrates. Ideal for flat stock printing, poster printing, aircraft interiors, and a myriad of other applications.

- Color Brilliance: Infuse your prints with a captivating gloss finish, enriched by a palette of vibrant and opulent colors that accentuate your designs.

- Outdoor Durability: Demonstrating unparalleled resilience, this ink offers an extended exterior life of up to three years on most substrates, ensuring your artwork remains vibrant and enduring.

- Application Diversity: Tailored to meet a spectrum of needs, from fine art serigraphs to polystyrene, Tyvek®, Tedlar®, polycarbonate, treated polyesters, pressure-sensitive vinyl, and aircraft interiors.

Technical Specifications:

- Screen Mesh: Optimal mesh range of 200 to 380 (80 to 150 cm) monofilament polyester is recommended.

- Stencils: Employ solvent and water-proof emulsions, with dual-cure emulsions highly recommended for enhanced durability.

- Squeegee Type: Embrace a sharp 70 to 85 single or multi-durometer polyurethane blade for superior performance.

Ink Additives and Thinning:

- Preparation: Prior to use, ensure thorough stirring of the ink.

- Viscosity Adjustment: Employ water for normal viscosity adjustments, limiting the addition to 5-10% by weight.

- Thinners and Retarders: Leverage TW-1820 for regular press viscosity reduction, while TW-1821 caters to slower print cycles. Use no more than 5-10% of thinner or retarder by weight.

- Enhanced Durability: Bolster chemical resistance by incorporating 5-10% of WB-1824 Activator by weight.

- Gloss Level Adjustment: Employ TW-4108 Flattening Powder (1-8% by weight) to modify gloss levels.

- Viscosity Boost: Amplify ink viscosity with TW-5008 Liquid Thickener (0.5-1% by weight).

Drying Parameters:

- Air Drying: Achieves dryness in 20 to 30 minutes at room temperature.

- Forced Drying: Rapidly dries in seconds at 90° to 150° F (32° to 66° C).

Adhesion Testing:

- Important Note: All substrates must undergo adhesion testing before production. Variations in materials, manufacturing batches, and storage conditions necessitate diligent assessment.

- Testing Method: Conduct adhesion tests using cross hatch and tape techniques to ensure optimal performance.

Responsibility and Usage Disclaimer:

- Prudent Use: Printers are responsible for conducting thorough adhesion tests on various materials to ensure compatibility and performance.

- Disclaimer: River City Supply and its affiliates shall not be held responsible for misuse, inadequate adhesion, or unsatisfactory results stemming from improper application or usage of the product.

Storage:

- Store below 100° F (38° C), safeguarding from freezing and preventing exposure to open flames and excessive heat.

Packaging:

- Available in quarts, gallons, five-gallon pails, as well as 30 and 50-gallon drums.

Safety and Handling:

- For comprehensive guidance, consult the Material Safety Data Sheet (MSDS) prior to usage.

Estimated Durability and Light-fastness:

- The exterior life of up to three years on most substrates (up to two years for Reflex and Ultra Blue) is attainable, though variables in production and usage may influence substrate durability.

Empower your printing endeavors with the unparalleled precision of TW Graphics® 5000 Series Water-Based Poster Ink. Redefine your approach to printing, merge technical finesse with artistic brilliance, and unveil a new era of creativity and enduring results.

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews