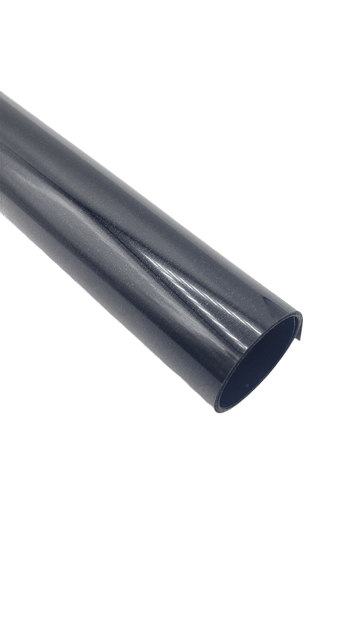

Siser EasyWeed 20” Matte Black Heat Transfer Vinyl – Premium Crafting Material

Siser Easyweed Matte Black Heat Transfer Vinyl is the ultimate solution for infusing your designs with an air of understated sophistication. This adaptable material is meticulously crafted for application on a variety of fabrics and surfaces, granting you boundless avenues for creative expression. Whether you’re enhancing t-shirts, hoodies, tote bags, or other items, Siser Matte Black HTV delivers a deep, velvety black tone that immediately captivates. Its user-friendly application process streamlines the development of sleek, professional-grade designs, catering to novices and skilled artisans alike. Robust and enduring, your artistic endeavors maintain their allure even through numerous wears and wash cycles. Whether your projects are driven by personal creativity or entrepreneurial pursuits, Siser Matte Black Heat Transfer Vinyl ensures that your designs leave an indelible mark.

$11.99

Description

Siser EasyWeed 20” Matte Black Heat Transfer Vinyl Key Features:

- Distinctive Hue: Matte Black Siser HTV boasts a sophisticated and distinctive matte black shade, perfect for a diverse range of designs and fabric tones.

- Effortless Application: Siser HTV in its matte black variant is celebrated for its user-friendly application. It adheres seamlessly to various fabrics and surfaces, catering to beginners and experienced crafters alike.

- Cutting and Weeding: Matte Black Siser HTV is a breeze to cut and weed, allowing the creation of intricate designs without the complexities of fine detailing.

- Versatility: Matte Black Siser HTV harmonizes with different fabrics, including cotton, polyester, cotton-poly blends, and more. This versatility empowers you to apply it to various types of garments and projects.

- Durability: Similar to all Siser HTV products, the matte black variant is engineered for resilience and enduring performance. It stands up to regular washing and wear without losing its luster or peeling.

- Layering: Matte Black HTV is excellent for layering on lighter fabrics. Often used as a base layer for multi-colored designs, it allows other hues to shine against it.

- Heat Endurance: Matte Black Siser HTV can be seamlessly applied using a heat press at the recommended temperature (typically around 305°F or 150°C), with no risk of discoloration or damage.

- Peeling Choices: Depending on your preference and the vinyl version, you can peel the carrier sheet either while it’s hot or after it cools down post-pressing, affording flexibility to your application process.

- Professional Look: Matte Black HTV lends a refined and professional finish to your designs. Its deep, solid matte hue makes it a favored pick for custom apparel enterprises.

- Adhesive Strength: Matte Black Siser HTV is engineered to provide strong adhesion to fabrics, ensuring your designs stay intact even after extended use.

Just like with any Siser HTV variant, it’s crucial to adhere to the manufacturer’s application instructions for optimal outcomes. Remember that specific product lines or updates may introduce variations while retaining the core features. Always consult the latest product information and recommendations from Siser to achieve the finest results for your projects.

Technical Specifications

| Application instructions (home iron) • Set iron dial between Cotton and Linen • Cover with Heat Transfer Cover Sheet or Multipurpose Paper • Place on flat, hard surface (ironing board not recommended) • Press iron with medium/firm pressure (do not slide iron) • Press each section of design for 10-15 seconds • If areas of design lift after application, replace cover sheet and re-press for 5-10 seconds • Peel carrier hot or cold |

Application Instructions (heat press) • Cover with Heat Transfer Cover Sheet or Multipurpose Paper • Preheat garment for 2-3 seconds • Apply design at 305°F/150°C • Use medium pressure for 10-15 seconds • Peel carrier hot or cold |

Cutter Settings:

|

Cricut: Blade: Standard Setting: Iron-on |

|

Silhouette Cameo: Blade: Standard, 2 Material: Heat Transfer, Smooth Speed: 8 Force: 4 |

|

Brother ScanNCut: Blade: Standard, 2 Cut Speed: 1 Cut Pressure: 4 |

|

Roland GX/GS-24: Blade: 45° Gram Force: 80-90 Offset: .250 Speed: 25-50 cm/s |

|

Graphtec: Blade: 45° Force: 8-9 Tool: CB09+0 Speed: 30 cm/s |

|

MH, SC2, LP3, and Titan1: Blade: 45°/60° Gram Force: 80-85 Speed: 300 mm/s *Blade Advancing Varies |

|

Titan 2 & 3: Blade: 45°/60° Gram Force: 80-85 Speed: 300 mm/s *Blade Advancing Varies |

Technical Specifications:

- Color: Black

- Width: 12 inches

- Thickness: 90 Microns/3.5 Mils

- Applies to: Cotton, Polyester, Cotton/Poly Blends

- Temperature: 305°F/150°C

- Time: 10-15 Seconds

- Pressure: Medium

To effectively apply Siser EasyWeed Heat Transfer Vinyl using a heat press, follow these step-by-step directions:

- Prepare Your Design: Ensure your design is properly cut and weeded, leaving only the desired elements on the carrier sheet.

- Preheat Your Heat Press: Turn on your heat press and set the temperature to 305°F (150°C). Allow the heat press to fully heat up to the desired temperature.

- Prepare Your Garment: Place the garment you intend to apply the vinyl onto the heat press platen. Smooth out any wrinkles and ensure the area you are applying the design to is flat and even.

- Position the Design: Lay the weeded design onto the garment, with the carrier sheet facing up and the adhesive side down onto the fabric. Position the design precisely where you want it to appear on the garment.

- Cover the Design: Place a Heat Transfer Cover Sheet or a piece of Multipurpose Paper over the design. This cover sheet prevents direct contact between the heat press platen and the carrier sheet, protecting both the vinyl and your heat press.

- Preheat the Garment: Close the heat press and apply light pressure for about 2-3 seconds. This preheating step helps eliminate any moisture and wrinkles from the fabric, ensuring better adhesion.

- Apply the Design: After preheating, lift the press and carefully remove the cover sheet or multipurpose paper. Place the heat press platen with the design back onto the garment. Apply medium pressure and maintain the temperature at 305°F (150°C). Press for 10-15 seconds.

- Peel Carrier Sheet: Once the pressing time is complete, lift the heat press and carefully peel the carrier sheet away from the design. You can peel the carrier sheet either when it’s still hot or after it has cooled down, depending on your preference. Pull the carrier sheet back over itself in a smooth, even motion.

- Cooling Period: Allow the garment to cool down for a few moments. This ensures that the adhesive sets properly, creating a lasting bond between the vinyl and the fabric.

- Final Inspection: After the garment has cooled down, inspect the design to ensure that it has adhered properly and that no edges are lifting. If any part of the design is not adhered well, cover it back up with the carrier sheet and reapply heat and pressure for a few more seconds.

Remember that specific heat presses may have variations in temperature accuracy and pressure application. It’s a good idea to perform a test application on a scrap piece of fabric or a sample before working on your final project to ensure that you achieve the desired results.

Following these steps should result in a successful application of Siser EasyWeed Heat Transfer Vinyl, creating vibrant and long-lasting designs on your garments.

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews