Inktek LB020 Bright White: Ultra-Soft Plastisol Ink for Cotton & Blends Printing

Introducing Inktek Bright White Plastisol Ink, the epitome of brilliance in screen printing. Crafted with precision and expertise, this high-performance ink sets a new standard for vibrant, eye-catching prints.

Inktek Bright White Ink is engineered to deliver unmatched brightness and clarity, ensuring your designs stand out with stunning visual impact. Its exceptional opacity guarantees crisp, flawless prints on a variety of substrates, from cotton to polyester blends.

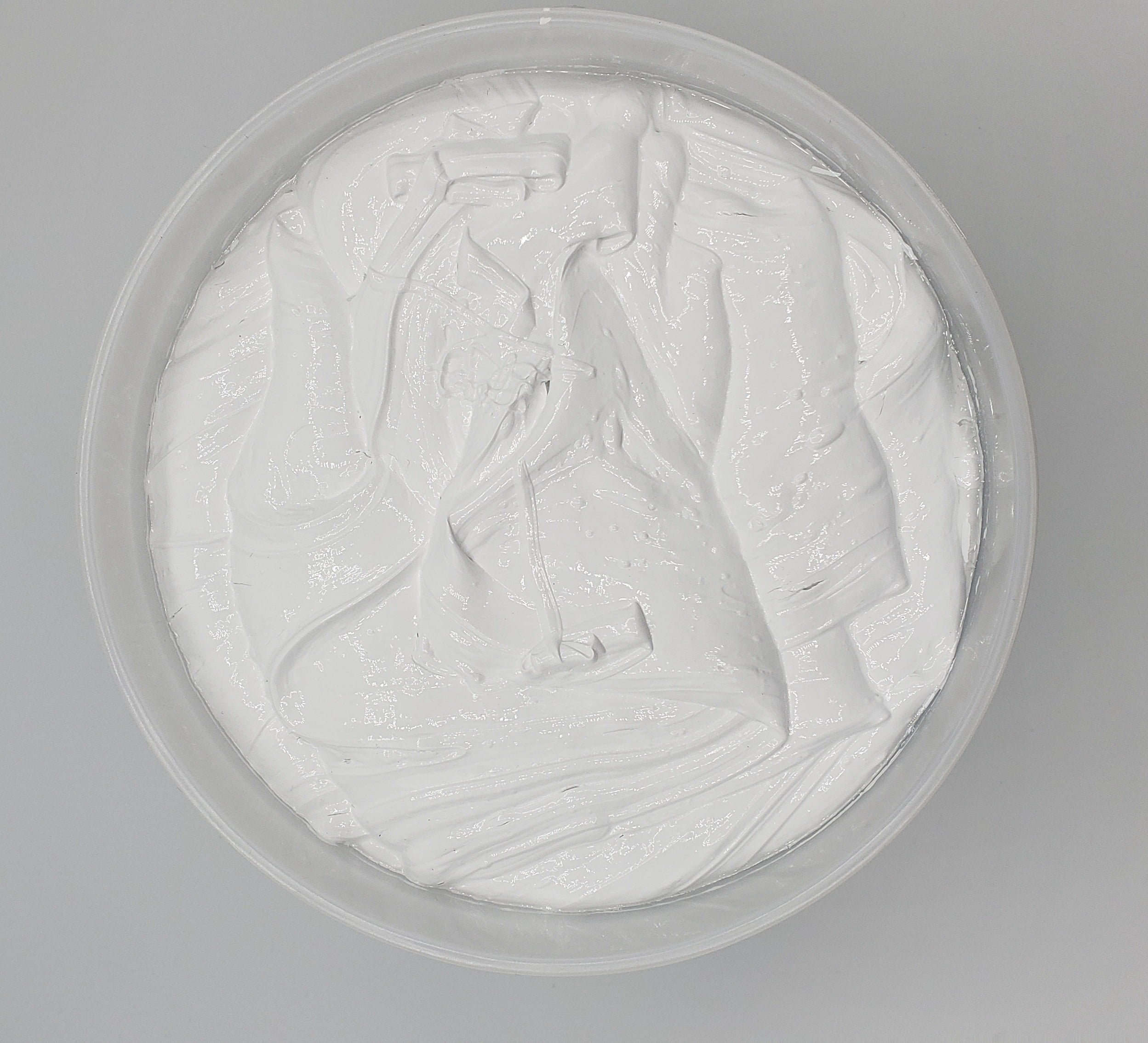

Experience effortless printing with Inktek Bright White Ink. Its smooth, creamy consistency and superior coverage make it a joy to work with, whether you’re a seasoned professional or just starting out in the world of screen printing.

But that’s not all – Inktek Bright White Ink incorporates a unique puff additive, giving it a slight lift that makes it more optically white and enhances coverage. This innovative feature ensures that your prints have a brilliant, dimensional appearance, capturing attention with every detail.

Furthermore, with a curing temperature of just 280 degrees Fahrenheit, Inktek Bright White Ink effectively prevents dye migration on polyester fabrics. This means your prints maintain their vibrant colors and sharp details, even after repeated washes.

Versatile and reliable, Inktek Bright White Ink is suitable for a wide range of applications, from intricate designs to bold graphics. Elevate your printing projects to new heights with this premium ink that promises nothing short of brilliance.

Choose Inktek Bright White Ink and unleash the full potential of your creativity. Transform ordinary prints into extraordinary works of art that captivate and inspire.

$38.99 – $7,800.00

Description

Key Features of Inktek LB020 Bright White Plastisol Ink:

- Superb Coverage: LB020 Bright White boasts a heavier bodied consistency that ensures outstanding coverage on a wide range of fabrics. Whether you’re printing manually or using automatic machines, this ink provides consistently brilliant results.

- Rapid Flashing: Say goodbye to long waiting times. LB020 Bright White flashes incredibly quickly, minimizing the downtime between prints. Its low after flash tack ensures a smooth and efficient printing process.

- Effortless Curing: Achieving professional-grade prints has never been easier. This ink cures effortlessly, leaving you with vibrant, long-lasting designs. Plus, it comes with virtually no processing or residual odor, ensuring a pleasant printing experience.

- Soft Feel: Manual printers, rejoice! LB020 Bright White offers a soft and comfortable feel on garments. Your customers will love the quality and comfort of the prints created with this ink.

- Bright Semi-Matte Finish: LB020 Bright White cures to perfection, delivering a bright semi-matte finish that truly stands out. Your designs will pop on any fabric, making this ink an excellent choice for creating eye-catching garments.

- Bleed Resistance: We understand the importance of clean and precise prints. That’s why LB020 Bright White exhibits excellent bleed resistance on most fabrics. Your designs will stay sharp and true to your vision.

- Ideal Underbase: Looking to create multi-colored designs? LB020 Bright White is an ideal underbase, providing a solid foundation for layering other colors. Your prints will have that extra depth and vibrancy you desire.

- Low Cure: LB020 Bright White cures at a low temperature of 280 degrees Fahrenheit, reducing the risk of dye migration on polyester fabrics. This ensures that your prints maintain their vibrant colors and sharp details, even after repeated washes.

Upgrade your screen printing game with InkTek LB020 Bright White Plastisol Ink, the go-to solution for achieving vivid, durable, and bleed-resistant prints. Elevate your designs, enjoy the softness for manual printing, and bring your creativity to life with this top-quality plastisol ink.

Technical Specifications

Inktek LB020 Bright White Plastisol Ink Application:

- Substrates: Best suited for 100% Cotton and Cotton/Blends. When printing on 100% polyester, it is highly recommended to use a blocker to prevent dye migration and achieve optimal results. Always ensure the material is clean and free from any contaminants before printing.

- Mesh Selection: Choose meshes between 86 – 305 Monofilaments based on the desired ink deposit and design detail.

- Gel Temperature (Gel Temp.): Your ink should achieve a gel temperature between 155° – 165°F, ensuring that the ink has gelled properly before proceeding to the fusion stage.

- Fusion: Cure the ink at a starting temperature of 280°F for a minimum of 1 minute 30 seconds. To expedite the curing process, you can elevate the temperature. However, bear in mind that temperatures exceeding 300°F elevate the risk of dye migration, which can compromise the print’s quality.

- Application Technique: Employ the direct printing method. This ink’s high opacity facilitates efficient wet on wet printing. Ensure each layer gels correctly before overprinting.

- Ink Modification: If you require adjustments to the ink, various additives are available for use. These include curable reducer, process clear, stretch additive, fashion base, finesse base, and more. To gain a deeper understanding of each additive, you can visit this link: Plastisol Inks Additives.

Storage Information:

- Safely store your Plastisol Ink between 65-90°F (18-32°C).

- Keep away from direct sunlight to maintain the ink’s consistency and active properties.

- For peak performance, utilize the ink within one year from its manufacturing date.

Features of Inktek LB020 Bright White Plastisol Ink:

- Non-phthalate: An environmentally-friendly formulation.

- High opacity: Produce vibrant prints with minimal ink layers.

- Low cure: Allows for curing at lower temperatures.

- High-speed: Engineered for rapid printing sessions with superb wet on wet performance.

- Reliability: The ink remains consistent, preventing drying within the screen or bucket, which guarantees prolonged and smooth printing sessions.

Note:

Always begin with a pre-test before embarking on a full production run. This ensures you achieve your anticipated results and minimizes wastage. After printing, consistently test the material to confirm the ink has thoroughly fused, assuring the print’s durability and quality.

River City Supply and its affiliates bear no responsibility for the misuse of the product. It is the printer’s sole responsibility to test and ascertain that the ink delivers the expected results prior to conducting a comprehensive print run. When printing on 100% polyester, it’s always advisable to utilize a blocker to mitigate dye migration.

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews