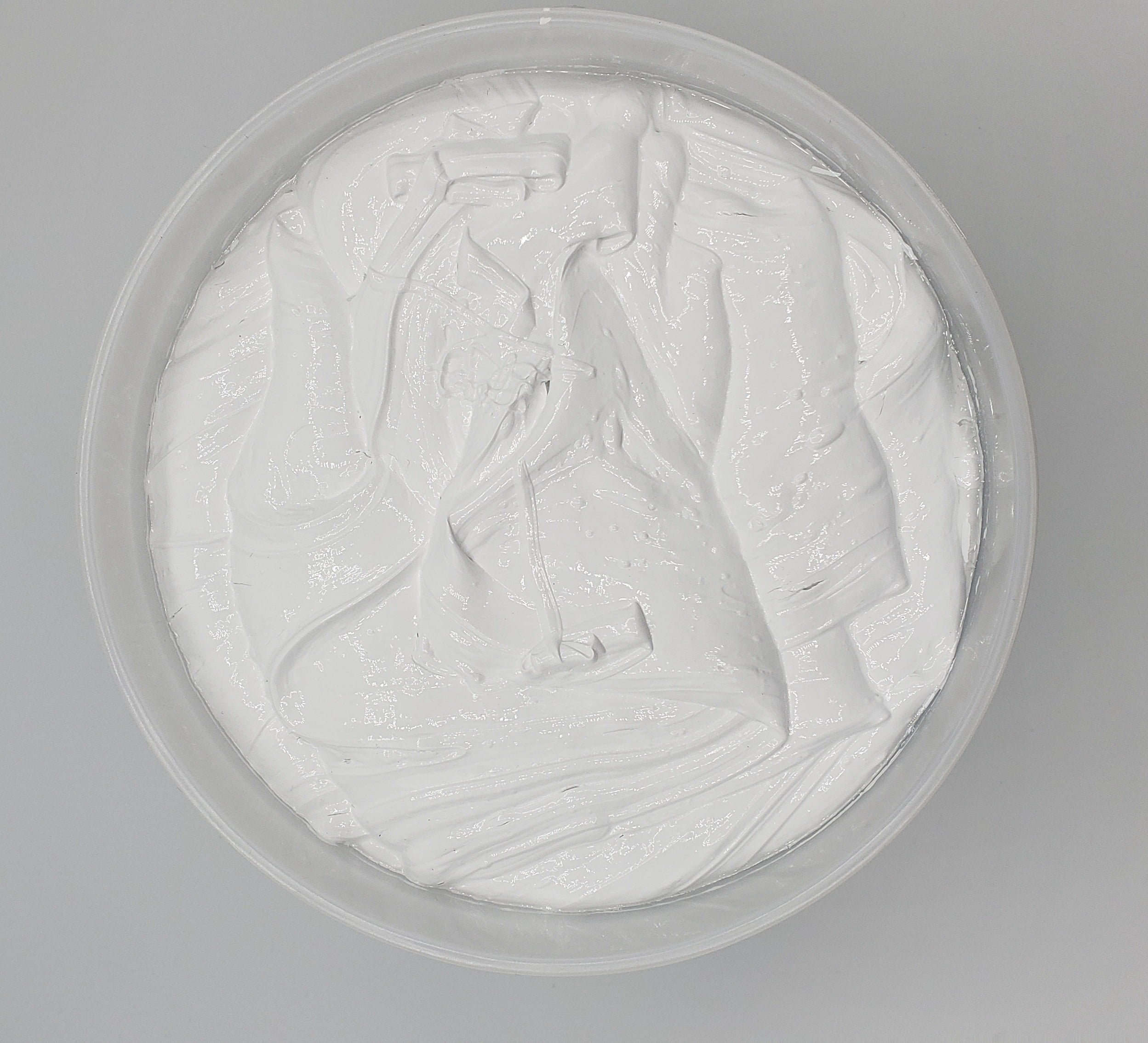

Inktek LB028 Bright Stretch White – Exceptionally Stretchy Plastisol Ink

Introducing Inktek LB028 Bright Stretch White Low Bleed Plastisol Ink – your premium solution for exceptional screen printing results. Our Non-Phthalate Bright Stretch White Plastisol is meticulously formulated to deliver unparalleled printability across a diverse range of applications. Designed with the needs of both automatic and manual printers in mind, this ink elevates your printing experience to new heights.

With its remarkable opacity and an optic-white hue, Inktek Bright Stretch White is the ultimate choice for a wide range of printing needs. Its matte finish imparts a touch of sophistication to your prints, while its unique stretch capability enhances versatility, ensuring your designs remain crisp and vibrant even on stretchable fabrics.

This ink stands out not only for its vividness but also for its ease of use. With excellent printability, it effortlessly flows through fine meshes, delivering intricate details with precision. Its low gloss level, combined with good flash properties, makes it an ideal choice for both stand-alone and under base applications, offering flexibility and consistent results.

$359.99

Description

Inktek Bright Stretch White Plastisol Key Features:

- Exceptionally bright white for striking prints

- Matte finish adds an elegant touch

- Enhanced with 10% Stretch Additive for versatility

- Suitable for fine mesh printing

- Functions as an under base flash white or stand-alone overprint white

- Exhibits impressive bleed resistance

- Non-Phthalate formulation for environmental consideration

- Virtually odorless for comfortable printing

- Cures at a standard 320 degrees

Inktek Bright Stretch White redefines screen printing with its exceptional properties, making your designs pop with vibrancy and quality. Elevate your prints with an ink that sets new standards and turns your creative vision into reality.

Technical Specifications

TECHNICAL SPECIFICATIONS

Inktek LB028 Bright Stretch White Plastisol Ink Application:

- Substrates: Best suited for 100% Cotton and Cotton/Blends. When printing on 100% polyester, it is highly recommended to use a blocker to prevent dye migration and achieve optimal results. Always ensure the material is clean and free from any contaminants before printing.

- Mesh Selection: Choose meshes between 86 – 305 Monofilaments based on the desired ink deposit and design detail.

- Gel Temperature (Gel Temp.): Your ink should achieve a gel temperature between 155° – 165°F, ensuring that the ink has gelled properly before proceeding to the fusion stage.

- Fusion: Cure the ink at a starting temperature of 280°F for a minimum of 1 minute 30 seconds. To expedite the curing process, you can elevate the temperature. However, bear in mind that temperatures exceeding 300°F elevate the risk of dye migration, which can compromise the print’s quality.

- Application Technique: Employ the direct printing method. This ink’s high opacity facilitates efficient wet on wet printing. Ensure each layer gels correctly before overprinting.

- Ink Modification: If you require adjustments to the ink, various additives are available for use. These include curable reducer, process clear, stretch additive, fashion base, finesse base, and more. To gain a deeper understanding of each additive, you can visit this link: Plastisol Inks Additives.

Storage Information:

- Safely store your Plastisol Ink between 65-90°F (18-32°C).

- Keep away from direct sunlight to maintain the ink’s consistency and active properties.

- For peak performance, utilize the ink within one year from its manufacturing date.

Features of Inktek LB028 Bright Stretch White Plastisol Ink:

- Non-phthalate: An environmentally-friendly formulation.

- High opacity: Produce vibrant prints with minimal ink layers.

- Low cure: Allows for curing at lower temperatures.

- High-speed: Engineered for rapid printing sessions with superb wet on wet performance.

- Reliability: The ink remains consistent, preventing drying within the screen or bucket, which guarantees prolonged and smooth printing sessions.

Note:

Always begin with a pre-test before embarking on a full production run. This ensures you achieve your anticipated results and minimizes wastage. After printing, consistently test the material to confirm the ink has thoroughly fused, assuring the print’s durability and quality.

River City Supply and its affiliates bear no responsibility for the misuse of the product. It is the printer’s sole responsibility to test and ascertain that the ink delivers the expected results prior to conducting a comprehensive print run. When printing on 100% polyester, it’s always advisable to utilize a blocker to mitigate dye migration.

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews