ROQ Tunnel Conveyor Dryer

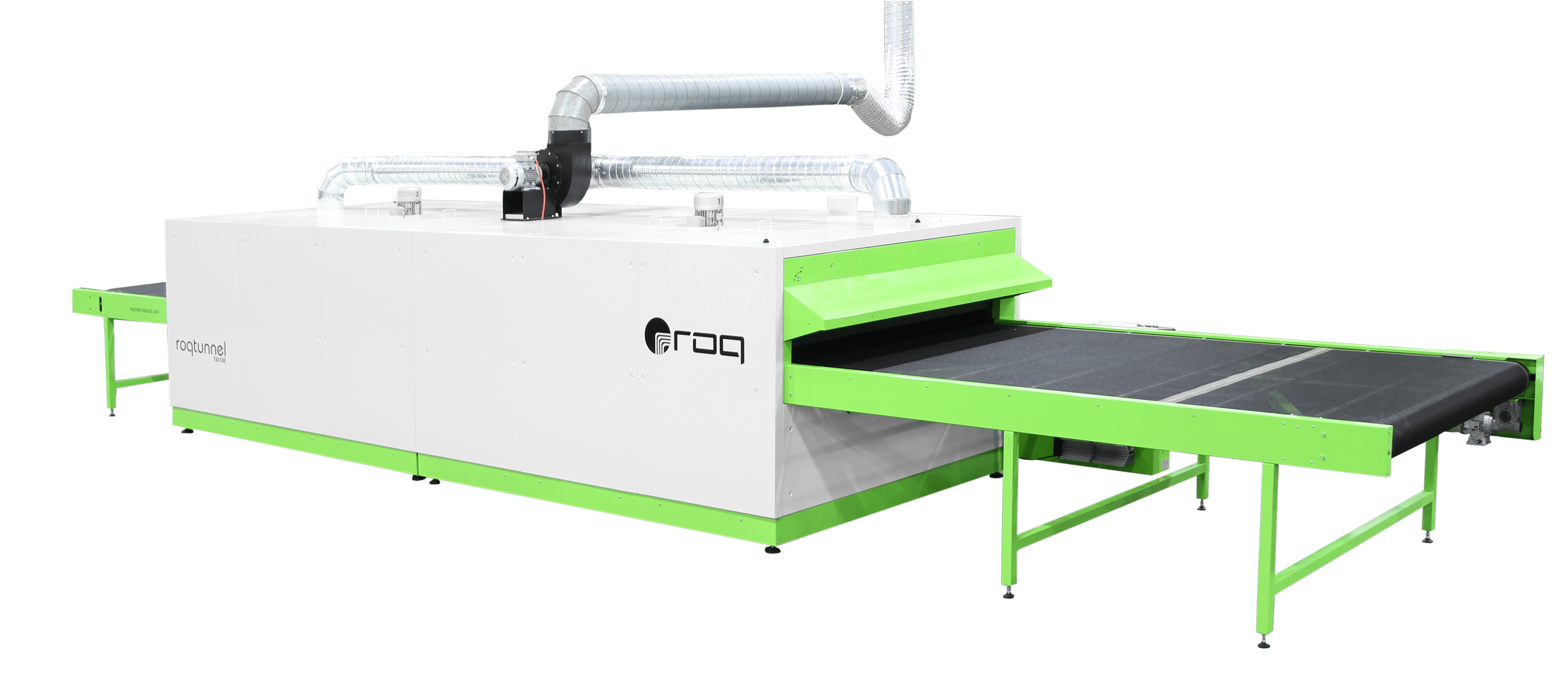

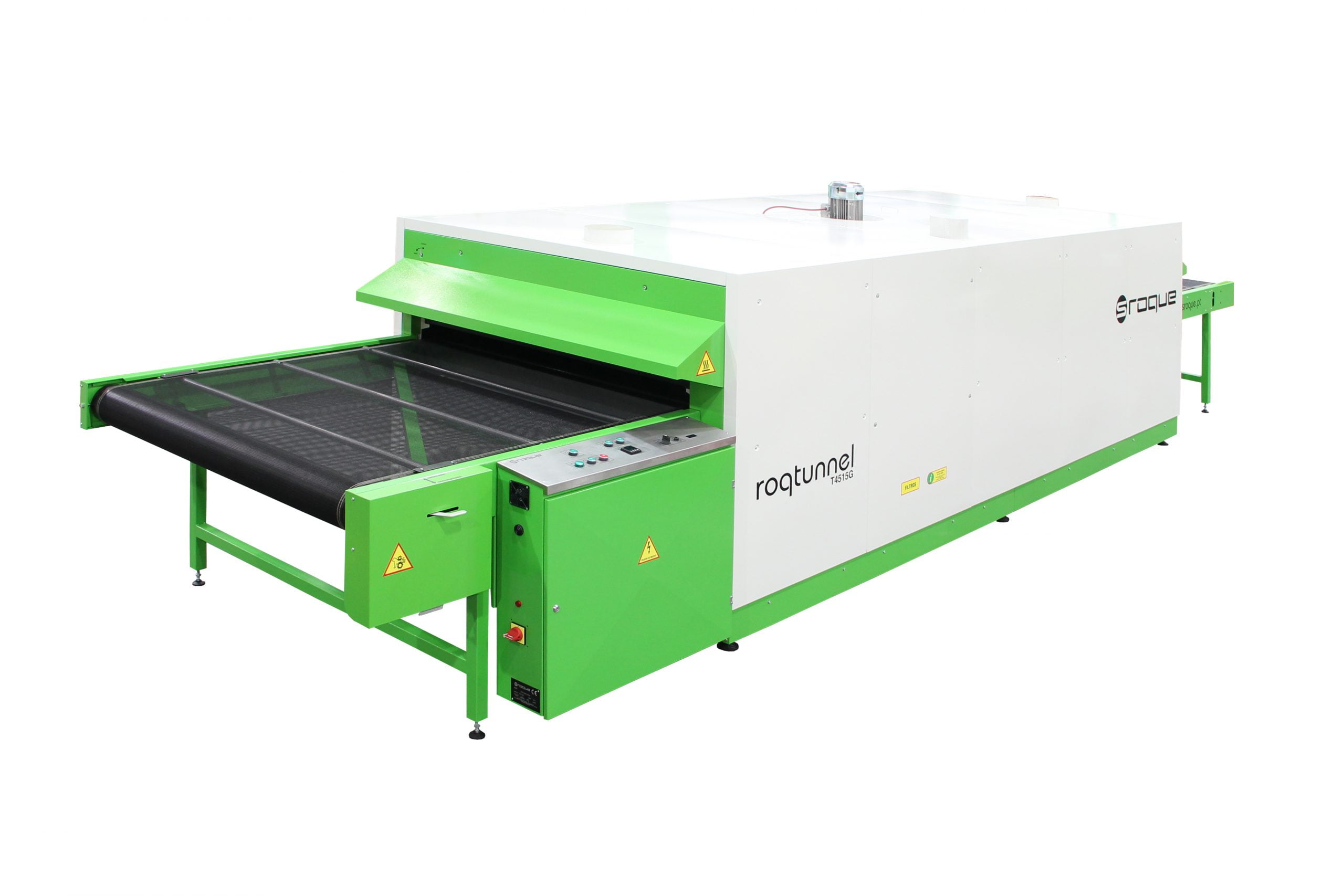

Introducing the ROQtunnel: A Versatile Screen Printing Dryer Platform

ROQ brings forth an extensive lineup of automated screen printing machines, ranging from carousel to oval models. Complementing this exceptional range is the ROQtunnel, a powerful platform that redefines the concept of a dryer. Contrary to being a singular dryer, the ROQtunnel is an incredibly sophisticated and refined system, meticulously honed over three decades through collaborations with specialists and customers worldwide. This culmination of expertise in various conditions, environments, and curing techniques has resulted in an absolutely versatile dryer platform.

Designed to seamlessly integrate into any screen printing shop, the ROQtunnel caters to diverse environmental conditions and available power sources. It can be effortlessly operated with electricity, gas, or even both, providing unparalleled adaptability and making it an ideal choice for global deployment. With a simple button press, printers can effortlessly switch between electricity and gas modes, effortlessly catering to the unique demands of different markets.

The ROQtunnel exhibits a maximum temperature of 200ºC, ensuring efficient and precise curing. An innovative Heat Exchanger feature prevents fabric yellowing caused by gas combustion, ensuring pristine printing results on every garment.

To meet the diverse needs of various print shops, we offer the ROQtunnel in an impressive array of 26 different versions. But we don’t stop there – customization is at the heart of the ROQtunnel. Simply share your specific requirements, and we will craft a tailor-made ROQtunnel that perfectly aligns with your production needs.

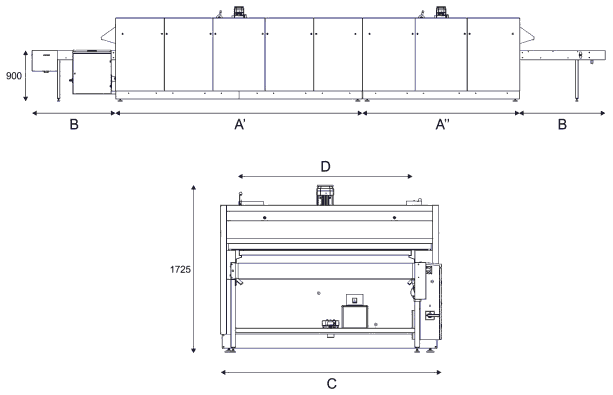

Configuration possibilities abound with the ROQtunnel, offering flexibility like no other dryer on the market. You have the freedom to adjust the infeed and outfeed lengths, as well as the width and length of the dryer to suit your workspace. The width and length of the belt(s) can be customized to match your print requirements. Moreover, the ROQtunnel can be configured with one or two belts, running in the same direction or opposite directions – the choice is yours. Every aspect of the ROQtunnel can be personalized to suit your unique workflow, offering unparalleled versatility.

While we grant you the freedom to customize every aspect of the ROQtunnel to suit your needs, there is one aspect we don’t change – its quality. ROQtunnel guarantees exceptional performance, reliability, and efficiency. The only thing not customizable is the color – but rest assured, the ROQtunnel’s outstanding capabilities will leave a lasting impression on your screen printing operation.

Description

Key Features of the ROQ Tunnel:

- High-Density Rockwool Thermal Insulation: The ROQtunnel is equipped with high-density rockwool panels for exceptional thermal insulation, ensuring efficient heat retention and precise temperature control during the curing process.

- Axial Flow Fan: The dryer incorporates an axial flow fan, facilitating constant and even circulation of hot air throughout the curing chamber. This feature enhances curing efficiency and consistency across the entire conveyor belt.

- Air Purification Filter: A dedicated air purification filter is integrated into the burner system of the ROQtunnel. This ensures that the air used for combustion is clean, preventing any contaminants from affecting the curing process or the final print results.

- Antistatic and Resistant Mesh Conveyor Belt: The ROQtunnel is equipped with a high-tensile strength PTFE coated conveyor belt that is antistatic and resistant to wear and tear. This ensures smooth and reliable transportation of garments through the curing chamber, minimizing downtime and maintenance.

- Digital Temperature Display: The ROQtunnel features a user-friendly digital temperature display, providing precise real-time temperature readings. This allows operators to monitor and adjust the curing temperature with ease for optimal results.

- Internal Exhaustion Header System: Each module of the ROQtunnel is equipped with an internal exhaustion header system. This feature facilitates efficient removal of fumes and moisture from the curing chamber, maintaining a clean and controlled environment.

- Contact Temperature Control: The ROQtunnel employs contact temperature control mechanisms to accurately measure and regulate the temperature of garments during the curing process. This ensures consistent and reliable curing results.

- Temperature Range: The ROQtunnel offers a wide temperature range, with a minimum temperature of 90°C and a maximum temperature of 200°C. This versatility enables efficient curing of various ink types and materials.

- Option of 2 Conveyors with Independent Speed and Direction: For enhanced productivity and customization, the ROQtunnel offers an optional configuration with two conveyors, each operating with independent speed and direction.

- Different Length Entry/Exit Openings: The ROQtunnel can be tailored to accommodate varying entry and exit lengths, providing flexibility to fit seamlessly into different production setups.

- GP (General Purpose): The ROQtunnel can be equipped with a General Purpose module, offering additional functionality and versatility for specific curing requirements.

- Power Options: The ROQtunnel offers the flexibility of being powered by gas, electricity, or both. This option allows print shops to choose the most suitable power source for their specific needs, making it adaptable to diverse environmental conditions and energy availability.

The ROQtunnel stands as a testament to ROQ’s commitment to delivering cutting-edge screen printing technology, providing unmatched performance, efficiency, and adaptability to elevate your printing operation to new heights.

Technical Specifications

Technical Sheets / Safety Data Sheets / Documents

Video

Reviews

Only logged in customers who have purchased this product may leave a review.

Reviews